Toolpath

Leading in toolpath technology

ModuleWorks offers the full range of toolpath calculations, from 2D and 2.5D, including turning cycles, to 3D roughing and finishing cycles and 5-axis machining for dedicated applications such as multiblade or port machining. ModuleWorks also provides process-specific toolpath calculations, for example for robot-driven laser welding. Most of the input data processed by the ModuleWorks software components is managed by an interface to the common solid kernel and CAD software. Once the geometry has been transferred, the toolpath can be generated and simulated and fully automated machining processes can be initiated.

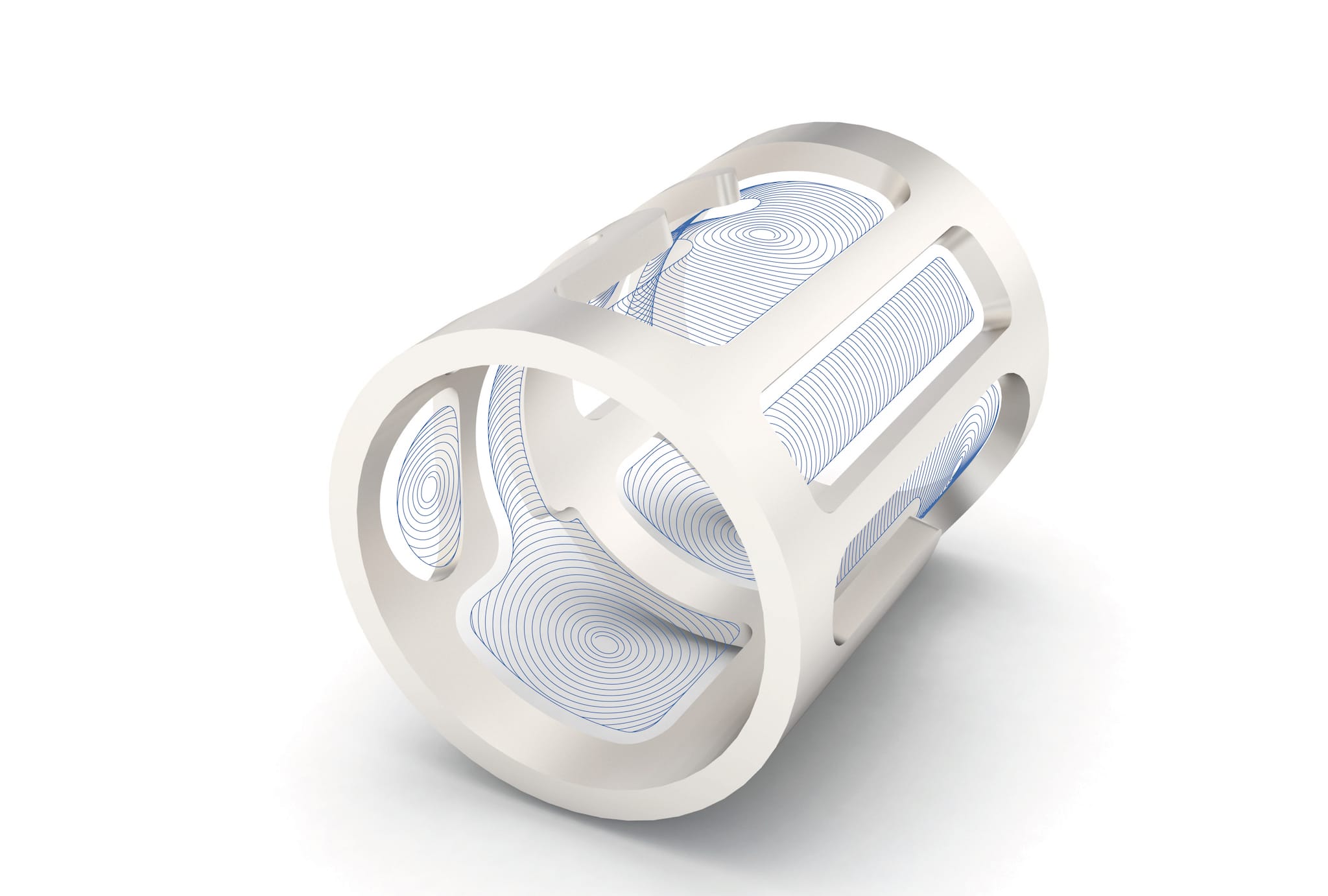

5-Axis Machining

The 5-Axis software component is an industry-proven product for high-quality 5-Axis machining. It is used by more than 60% of the world’s leading CAM vendors and is the ideal solution for companies who require integrated 5-Axis machining technology. The ModuleWorks solution includes a wide and flexible range of toolpath generation strategies and postprocessing tools to support the full range of 5-Axis machine tools available on the market today.

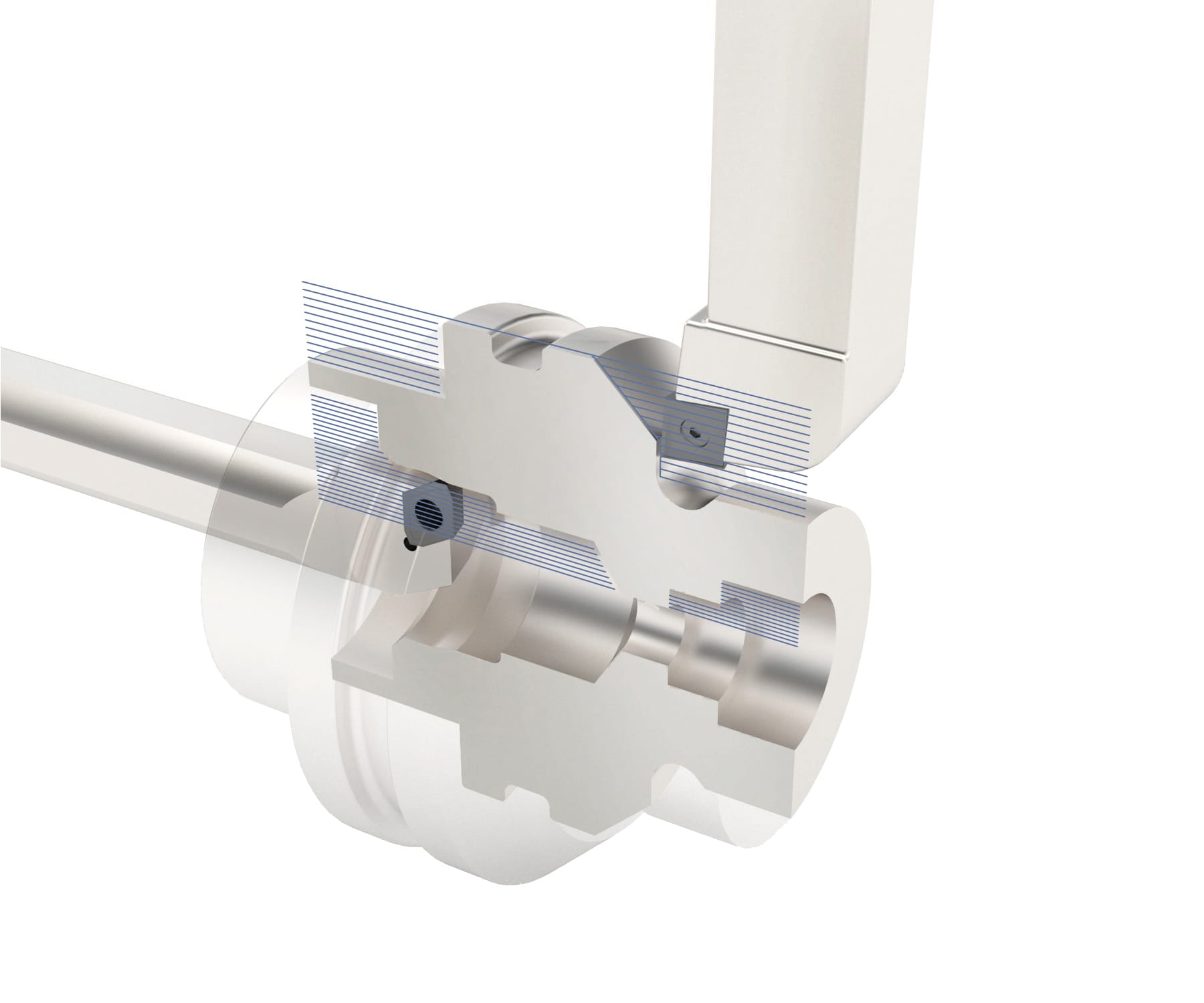

4-Axis Machining

The ModuleWorks 4-Axis software is a subset of the 5-axis component for applications that require shaft-type parts for automotive camshaft/crankshaft machining, rotary dies and oilfield components. The dedicated 4-Axis module incorporates leading strategies with a high level of automation that empowers operators with full flexibility and control for easy machining of high-quality parts with fully gouge-protected link and approach moves.

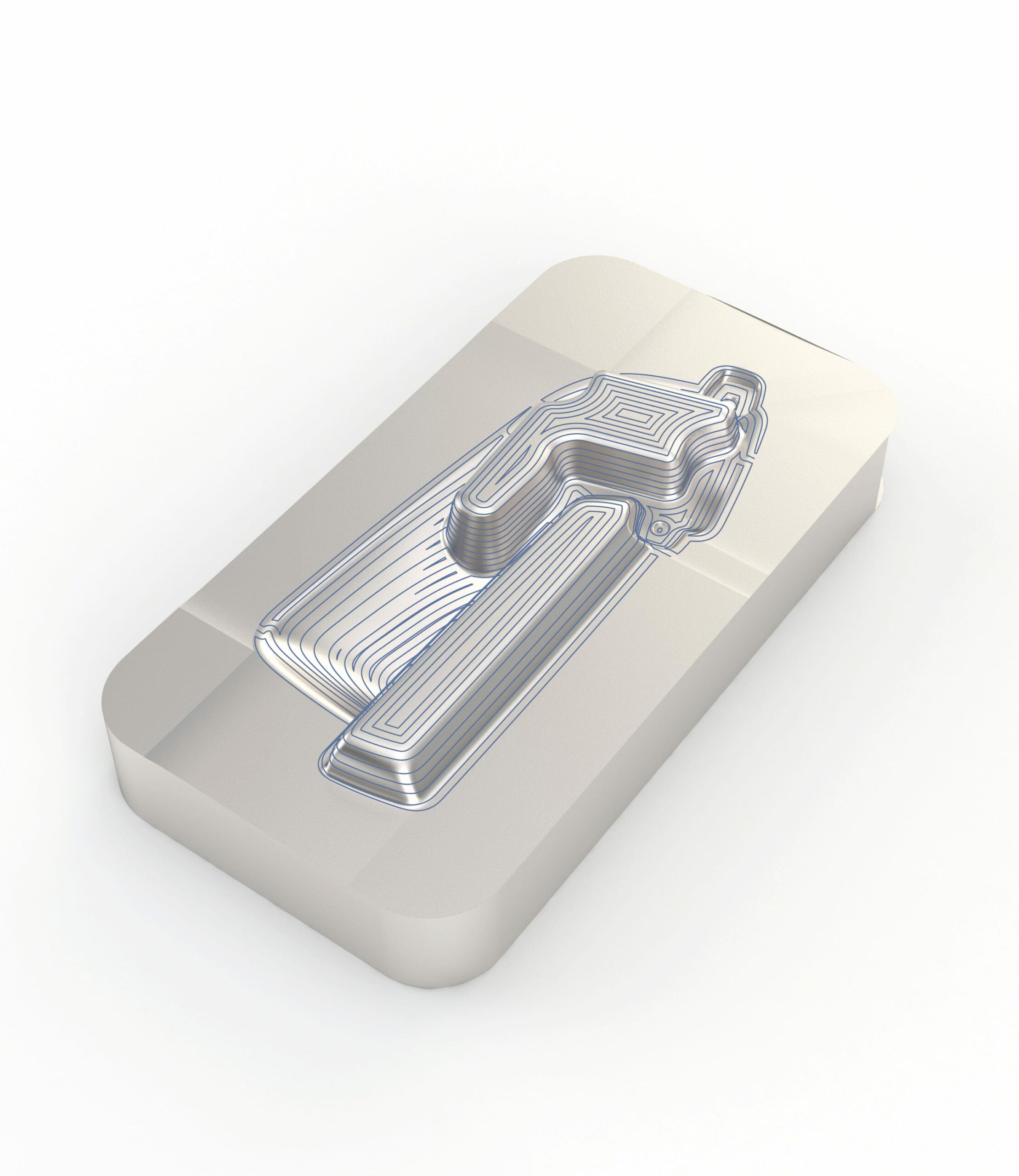

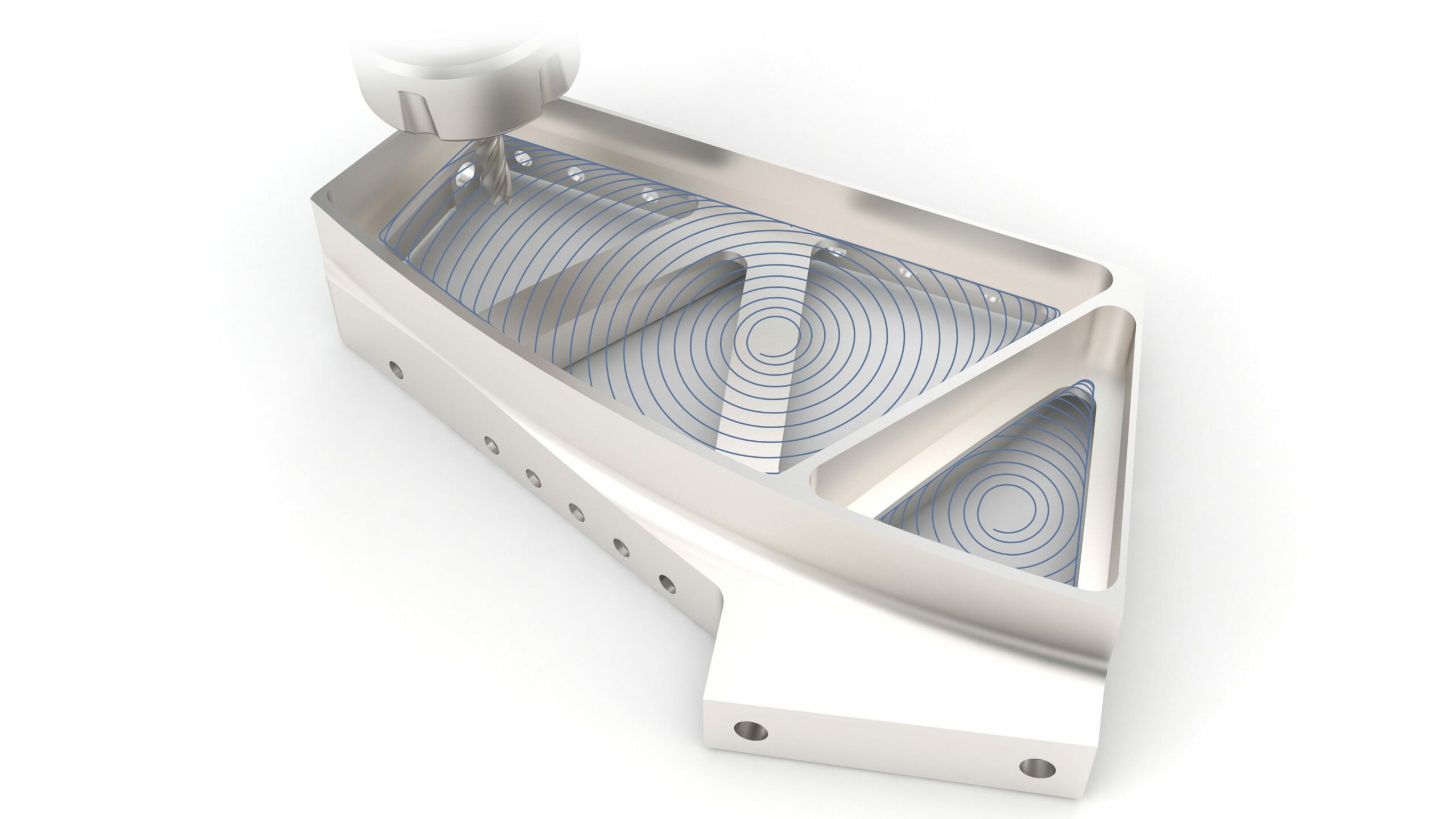

3-Axis Machining

ModuleWorks offers advanced software technology to optimize 3-axis machining, empowering CAM software developers and CNC controller manufacturers with high-performance components for collision-free roughing, rest-roughing, finishing, and rest-finishing. Designed for seamless integration, these components enable rapid, next-level development of innovative 3-axis solutions across a range of industries, including aerospace, automotive, mold and die, and production machining.

Let the Numbers Talk

market share worldwide

make us the world market leader in CAM technology.

customers

trust in the quality of our products and value our partnership.

years of ModuleWorks

are just the beginning.

Turning

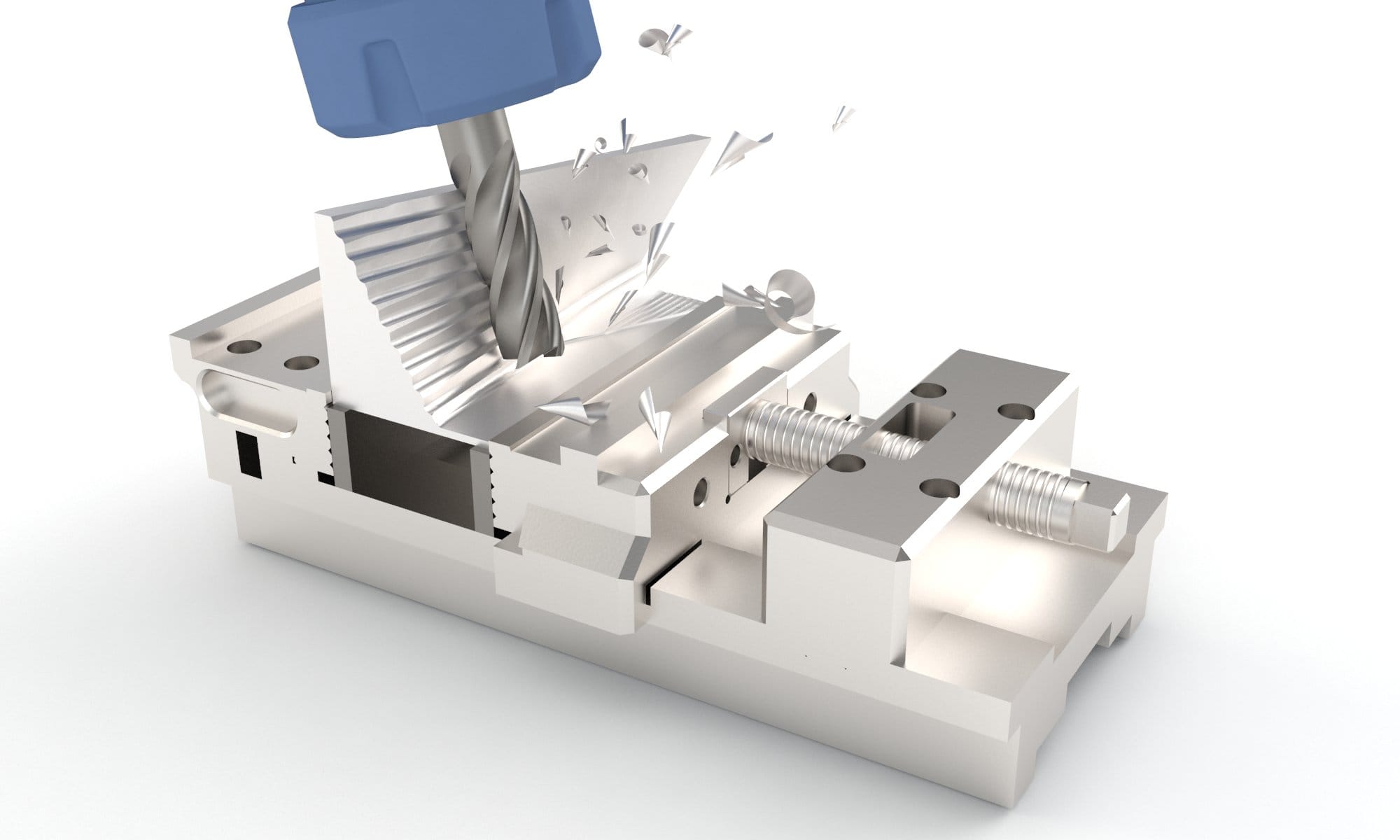

Adaptive Roughing

The adaptive roughing strategy uses the full potential of cutting and machine tools to increase the productivity and profitability of roughing processes.

Our smart toolpath cycles, used in combination with our conventional roughing patterns, increase the value of the whole solution, especially for expensive roughing processes. We apply this technology from 3-axis z-level patterns to 4-axis and full 5-axis roughing as well as turning-cycles.